The number of cracks in autoclaved sand aerated concrete wall is more than that in shale modulus brick wall, but much less than that in fly ash brick wall. The main reasons and corresponding preventive measures shall be:

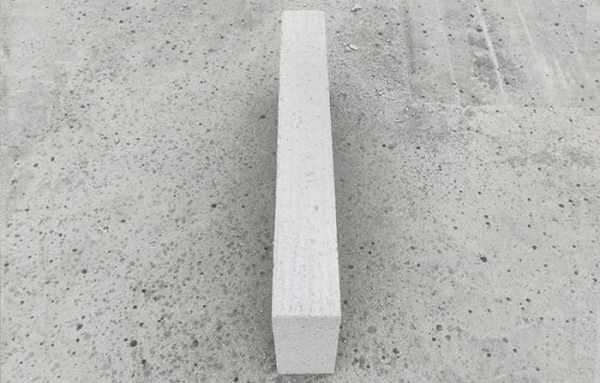

1、 Autoclaved aerated concrete blocks Large drying shrinkage, autoclaved sand Aerated concrete block High pressure steam curing has greatly reduced the shrinkage value of products.

However, because its composition material and structure determine the dry shrinkage and wet expansion of products, its large dry shrinkage value is 0.5mm/m, which is 0.1mm/m higher than the dry shrinkage value of shale modulus brick, so autoclaved sand aerated concrete masonry is more prone to cracks than shale modulus brick masonry.

In order to minimize shrinkage cracks on walls, manufacturers with relatively complete quality management system shall be selected for early procurement, and rain shall be avoided during storage and transportation. It is recommended to select blocks with strength above A5.0.

In terms of structure and construction measures, large area walls are divided into small pieces by setting structural columns and ring beams to reduce the number and width of cracks.

For the joint treatment at the junction of autoclaved sand aerated concrete block and reinforced concrete beam column, it is recommended to fill the gap with fine aggregate concrete or cement mortar added with waterproof agent, which can effectively prevent leakage at this part. The surface is then paved with alkali resistant fiber mesh cloth or steel wire mesh to enhance the tensile force, which can effectively reduce the number of cracks.

2. The temperature difference causes expansion cracks, which mainly appear on the exterior wall, in a full-length state, and are easy to cause water leakage of the exterior wall.

The main reason is that the thermal resistance of the block material is large, resulting in a large temperature difference between the inside and outside of the masonry, and the temperature stress inside the wall, so it is easy to produce microcracks. The external wall surface can be covered with alkali resistant fiber mesh cloth or steel wire mesh, which can achieve good results.

3. The unreasonable construction method of masonry causes cracks. Because the block has the drying shrinkage characteristics, the moisture content of the block must be strictly controlled during masonry.

According to whether the masonry surface is watered or not, the masonry methods can be divided into dry method and wet method; Dry construction means that the masonry blocks are directly constructed with bonding mortar without watering, and the mortar joint thickness is controlled within 5mm.

Mainly used for single material insulation system; Wet construction means that the masonry surface of the block shall be properly watered before masonry, so that the water is immersed in 5~10mm, and the masonry mortar is used. The thickness of the mortar joint shall be controlled within 15mm. For wet construction, the influence of the thickness of the mortar joint on the thermal resistance of the masonry shall be considered, so the designer shall indicate the masonry method.

The above two kinds of mortars are modified mortars, and their water retention shall meet the water requirements for hydration during masonry and mortar hardening.

The use of ordinary mortar for masonry will cause the mortar to lose water at an early stage, resulting in looseness and insufficient strength, and it is easy to cause cracks along the mortar joints.

Before masonry, mark the number of bricks according to the height of the block and the thickness of the mortar, mark the position of the leveling layer and the tie bar, and then conduct leveling and anchoring after the tie bar.

During construction, the masonry shall be built from both ends of the wall to the middle direction to ensure the reliable connection between the block and the column and the tie bar, avoid vertical cracks, and facilitate the construction of the block at the tie bar.

During block construction, the upper and lower overlapping shall be more than 1/3 of the block length, and the mortar joint shall be horizontal and vertical. It is suggested to use special adhesive instead of ordinary cement mortar for masonry, which saves time and labor and greatly reduces the probability of wall cracking.

The content of this article comes from the network. If you have any questions, please contact me to delete it!