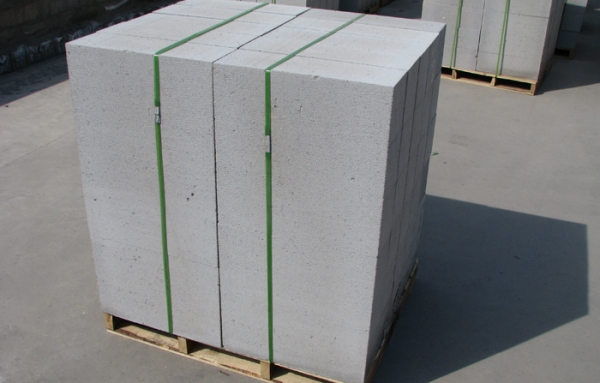

There are two main types of application in the building system: the first type is the multi-storey mixed structure, which mainly gives play to the advantages of good thermal insulation performance of aerated concrete. Under the condition that the original horizontal bearing system of multi-storey buildings remains unchanged, it is the most economical thermal insulation method among similar systems to use it as an external wall material as well as thermal insulation material. The second type is reinforced concrete frame structure system, which can be used as external wall and internal partition wall, which can give full play to the advantages of lightweight aerated concrete products and can be widely used in high-rise buildings.

In view of the increasing national requirements for building thermal insulation and energy conservation, corresponding laws and regulations have been issued. For example, Beijing has started to implement the energy conservation target of 65%. The application in the "external insulation" system is mainly used as the external insulation of concrete hollow block walls and the external insulation of reinforced concrete walls. Its structure has passed the engineering practice and can be widely used in the external insulation of other materials, such as brick walls, porous bricks, lightweight blocks and other products. The construction principles are the same. Aerated concrete is probably one of the most economical "external insulation" systems currently used for external insulation of walls.

Thermal insulation application of various parts of the building. The development of low-density aerated concrete products has broadened its application scope, such as roof, ground, external insulation of exposed beams and columns that are easy to produce "hot bridges", and non heating buildings and floors. In the past, due to low energy saving standards, it was common to use B05 products. However, due to the improvement of energy saving standards, the use of B05 gas products will increase the thickness of application on roofs and other parts. Therefore, B05 gas products are gradually replaced by other lightweight and efficient thermal insulation materials, such as foam polystyrene board. However, practice has proved that such lightweight materials have low thermal conductivity, low heat storage coefficient and enthusiasm index, poor thermal insulation performance, and are not suitable for roofing, but there is no suitable material to replace them at present. The development of B035 grade or lower dry density products has undoubtedly opened up space for roof thermal insulation materials in northern cold regions, especially in northern China. When the aerated concrete is on the same plane as the beam and column as the external wall material, low-density aerated products are used as the external insulation of the beam and column to make the entire wall material consistent, which not only makes the surface treatment simple, but also reduces the temperature deformation and is not easy to crack in this part. Non load bearing partitions.

The thermal conductivity of aerated concrete is generally 0.11-0.18 kcal/m 0 hour 0 degree, which is only 1/4-1/5 of that of granular soil brick and lime sand brick (the thermal conductivity of granular soil brick is 0.4-0.58 kcal/m o hour o degree; the thermal conductivity of lime sand brick is 0.528 kcal/m o hour o degree), which is about 1/6 of that of ordinary concrete. Practice has proved that the thermal insulation effect of 20 cm thick aerated concrete wall is equivalent to that of 49 cm thick clay brick wall, and its thermal insulation performance is also much better than that of 24 cm thick brick wall. This greatly reduces the thickness of the wall, correspondingly expands the effective use area of the building, saves the thickness of building materials, improves the construction efficiency, reduces the project cost, and reduces the self weight of the building.

The three major concerns when using aerated concrete as partition wall are:

1. Can it be used in rooms with high humidity, such as toilets and bathrooms. In fact, there is a misunderstanding about aerated concrete products, thinking that the water absorption rate of foam products must be large and fast, but actually it is small and slow. At present, the walls of toilets and bathrooms are tiled to the top in general practice, and the waterproof layer of the wall is more than 1.8m, so as long as the waterproof layer is slightly higher, the waterproof of the wall is very safe, and there is no problem in the application.

2. Plastering is easy to crack. There are many factors for plaster cracking, and this problem can be solved from two aspects: first, structure and construction; The second is plastering materials and interface materials. In terms of plastering materials, such as plastering gypsum developed in northern areas, the cracking problem of interior wall plastering has basically been solved.

3. Fixation of partition wall and superstructure. Elastic method shall be adopted, and angle steel shall be used for clamping in seismic area.

Interior and exterior wall decoration. In the application process of aerated concrete, everyone is concerned about the following problems: first, the problem of plaster cracking as described previously; 2、 Whether the aerated concrete wall can do various high-end decoration like other wall materials, such as dry hanging stone, metal curtain wall, etc. First of all, two aspects should be considered to solve the problem of plaster cracking: in terms of structure, the prominent problem is the intersection of two different materials, as well as the location of grooving, opening and filling on the wall. The solution is mainly to strengthen the location with polymer mortar and glass fiber mesh cloth; The problems of the plastering layer itself are mainly based on the interface treatment of the base course with the material characteristics of the aerated concrete, and the material properties of the bottom plastering layer are required to be close to the material properties of the aerated concrete, especially the strength should not be too high, while the surface course method is not much different from the general traditional method. The second is to solve the possibility of high-end decoration of walls. According to practical experience, for various stone or metal plate surface courses, embedded parts can be set on the beams and columns between layers, and concrete cast-in-situ strips are set at every 1.2m~1.5m of the wall, and embedded parts are set. The keel or reinforcement mesh connected to the decorative surface course is fixed on the embedded parts, and the surface materials are finally installed according to the conventional method. That is to say, the design principle is that the weight of the outer heavy decoration is borne by the cast-in-place belt between the beam column and the wall of the building structure.