Autoclaved aerated concrete blocks The decrease of splitting tensile strength of is simply caused by cracks, which will bring damage to the use of construction. So during the autoclave Aerated concrete block Maintenance is that the process determines the composition of the product's intrinsic function. What problems do autoclaved aerated concrete blocks simply present when they are made? Let's introduce it.

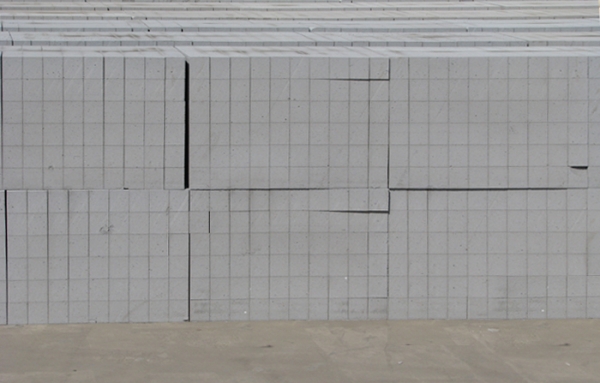

1、 Cracks: Cracks in autoclaved products are common damages in the production of aerated concrete, which may be caused by raw materials or maintenance itself. When the green body strength is too low, steam curing maintenance is also easy to damage the green body. When the maintenance criteria are not appropriate, the whole mold body may have arc cracks. Other cracks, although not formed by maintenance, were found after protection, and were greatly affected by water material ratio, pouring temperature, cooperation ratio, and the storage environment of green body.

2、 Adhesion: Adhesion refers to the adhesion between the product blocks of the kettle, which is caused by many reasons, but this phenomenon mainly occurs after maintenance. Adhesion is actually the cutting and cracking of the gap, which can not isolate the green bodies on both sides of the gap. During maintenance, because of the hydrothermal composition reaction, hydration products extend and crystallize through the material fragments in the gap, Then the separated billets are connected again. The elements of adhesion are water, the proportion of residual materials in the gap, and the dissolved amount of sio2 and CaO in the water. That is to say, the adhesion is related to the moisture in the green body, the width of the slit and the ingredients. Practice shows that the adhesion is closely related to the strength of the green body when it is cut, the water material ratio, the pouring temperature, the static stop time, and the maintenance criteria.

3、 Bursting: Bursting is mainly manifested in that the appearance of the product falls off in pieces when it comes out of the kettle, forming a pockmarked surface. The main reasons for its occurrence are the burnt lime particles or the particles of other materials that are not stirred evenly.

The burnt lime particles did not digest during the static stop of pouring, but rapidly digested under the high temperature after entering the kettle, accompanied by the volume expansion, causing damage to the products. The digestion of unmixed lime aggregates after static stop or cutting may have caused damage to the green body. During maintenance, the damaged parts will be stripped off due to the large expansion value of lime aggregates. The aggregates of other materials also swell at the later stage due to slow water absorption, which will damage the products.

4、 External pockmarks and collapses: The external pockmarks and collapses are mostly composed of condensed water in the pipes. In the past, the inlet pipe of the kettle was mostly placed above, so that when the inlet air was heated, the condensed water in the pipe directly impacted the upper body, and then caused damage. At present, most cauldrons have been changed to air inlet on both sides, but the air distribution hole of the air inlet pipe should also be avoided from directly facing the green body.

5、 Mucous membrane: Mucous membrane is a kind of damage that often appears in the maintenance phase of pouring and cutting. No matter in which phase, the reason for its occurrence is roughly the same, that is, one of the baseplates is improperly oiled, or the baseplate does not absorb oil, or the selected oil viscosity is too low. When the bottom plate does not absorb oil thoroughly, it is easy to be washed away by the slurry during the pouring process. After pouring, the coating is also easy to enter the green body, which not only damages the barrier effect, but also reduces the strength of the bottom layer of the green body, making it easy to attack the mucous membrane. Secondly, some static stop tables are equipped with steam heating tubes. When the steam temperature is too high, it is easy to make the base plate coating layer enter the green body, and then form a mold. Third, the bottom plate is not cleaned, and the adhesive on the floor forms a firm combination with the green body cast from the beginning. After repeated maintenance, the adhesive on the bottom plate becomes stronger and stronger with the floor, thus forming a repeated adhesive mold.

6、 Heart generating: sometimes the middle part of the products coming out of the kettle is dark, which is called "heart generating" or "black heart". Even the whole product is dark and lusterless, which is composed of no steaming. First, check whether the steam meets the requirements, whether the maintenance criteria are feasible, and whether the relevant instruments and equipment are in good condition; Then check the status of raw materials and make adjustments.

The content of this article comes from the network. If you have any questions, please contact us!