Product benefits

Light weight

Shenyang gas filling block The general mass is 500-700 kg/m3, which is only 1/4-1/3 of clay brick and lime sand brick, and 1/5 of general concrete. It is the lighter type of concrete, and is suitable for infill walls built in high-rise buildings and load-bearing walls built in low floors. Using this material, the dead weight of the whole building can be reduced by more than 40% compared with that of ordinary brick concrete structure. Because the deadweight of the building is reduced and the seismic damage is small, the seismic capacity of the building is greatly improved.

Thermal insulation

The thermal conductivity of aerated concrete is generally 0.11-0.18W/m · K, which is only 1/4-1/5 of that of granular soil brick and lime sand brick (the thermal conductivity of granular soil brick is 0.4-0.58W/m · K; the thermal conductivity of lime sand brick is 0.528W/m · K), which is about 1/6 of that of ordinary concrete. Practice has proved that the thermal insulation effect of 20 cm thick aerated concrete wall is equivalent to that of 49 cm thick clay brick wall, and its thermal insulation function is also much better than that of 24 cm thick brick wall. In this way, the wall thickness is greatly reduced, the effective use area of the building is correspondingly expanded, the thickness of building materials is saved, the construction power is increased, the project cost is reduced, and the self weight of the building is reduced.

High strength

After experiment, Aerated concrete block The compressive strength is more than 25kg/cm2, which is equivalent to the compressive strength of 125 # clay brick and lime sand brick.

Seismic resistance

During the earthquake in Fengnan, Tangshan and other places with a magnitude of 7.8, according to the post earthquake survey, only a few new cracks appeared in the construction of aerated concrete, while the construction of brick and concrete structures almost collapsed, making a sharp contrast between the two buildings, which are not far apart and have the same structure but different materials. Through analysis, it is believed that this is because the aerated concrete has light volume weight, good overall function and small inertia force during earthquake, so it has certain seismic ability. This will be of great benefit to our earthquake prone country.

Processability

Aerated concrete has good processing function. Able to saw, plane, nail, mill and drill. In addition, reinforcement can be added during fabrication. It brings great convenience and flexibility to the construction.

High temperature resistance

When the temperature of aerated concrete is below 600 ℃, its compressive strength increases slightly. When the temperature is about 600 ℃, its compressive strength is close to the compressive strength at room temperature, so the fire prevention function of aerated concrete as a building material meets the national first class fire prevention specifications.

Sound insulation

It can be seen from the pore structure of aerated concrete that because the internal structure of aerated concrete is the same as that of bread, it is evenly scattered with many closed pores, so it has the sound absorption function that is not possessed by ordinary construction materials.

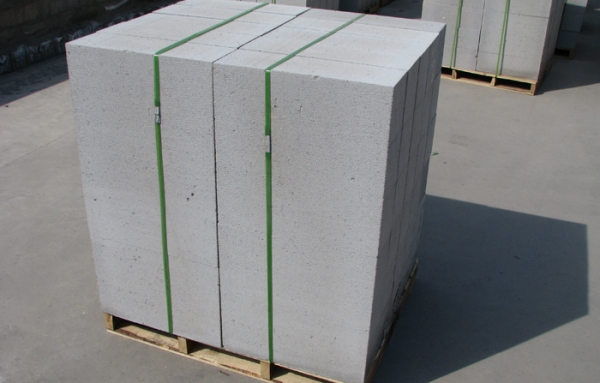

Mechanization

Prefabrication of aerated concrete for assembling large plates can save the stacking area of finished products; Save masonry labor; Construction operation is reduced; The site construction progress is accelerated and the construction power is increased.

adaptability

It can be customized according to different local raw materials and conditions. The raw materials can be river sand, fly ash, ore sand, etc. And it can be used as waste, which is beneficial to environmental protection and turns waste into treasure. The strength value of the aerated concrete block made by the aerated concrete equipment is relative to a certain water content, which is called the reference water content. However, the scale of the reference water content of strength varies from country to country. For example, the standard water content in German, European Community and British specifications is (6 ± 2)%, The starting point is that the final moisture content of the product is 2% - 8% after it is put on the wall; In Sweden and other countries, the air drying condition of aerated concrete blocks is taken as the benchmark, that is, the moisture content is (10 ± 2)%; In China, the evaluation of the compressive strength grade is based on the Test Method for Autoclave Gasification Function (GB/T11969-2008) - "The compression test requires a moisture content of 8~12%". (GB/T11971-1997 Test Method for the Function of Aerated Concrete stipulates that the compressive strength of products should be tested at 25% - 45% of the mass moisture content, that is, 25% - 45% of the moisture content in the stable stage of the strength, which is very different from the water content in the practical wall, so it will affect the quality assessment of the compressive strength of aerated concrete, and has been abolished).

The content of this article comes from the Internet. If you have any questions, please contact us!