Shenyang gas filling block The manufacturer reminds you to avoid Aerator block When cracks occur, we should pay attention to the following aspects during construction design:

1. When the length of the wall exceeds 5m, the reinforced concrete structural column shall be set in the wall to reduce the deformation deflection of the upper beam. For the wall above 7m, in addition to two structural columns, a 120mm high horizontal waist beam shall be set between the two structural columns to effectively eliminate vertical cracks.

2. Reinforced concrete columns are set on both sides of window openings in 1-2 rooms on both sides of east and west gable.

3. Add 80-100mm thick C20 under the window opening, with 2 inside Ф 8 Reinforced concrete strip, 2 Ф 8 The reinforcement is connected with the frame column to reduce the cracking caused by stress concentration.

4. At the junction of concrete and aerated block, and around the electrical pipeline and switch box, add steel wire mesh and place it in the rough surface of the painting layer.

5. Masonry mortar shall be made of materials similar to the elastic modulus and linear expansion coefficient of the block as far as possible; The additive containing glass fiber is added into the plastering mortar to increase the crack resistance of the plastering layer.

6. SKK elastic coating is used for exterior wall, which can make up for wall cracks below 1mm.

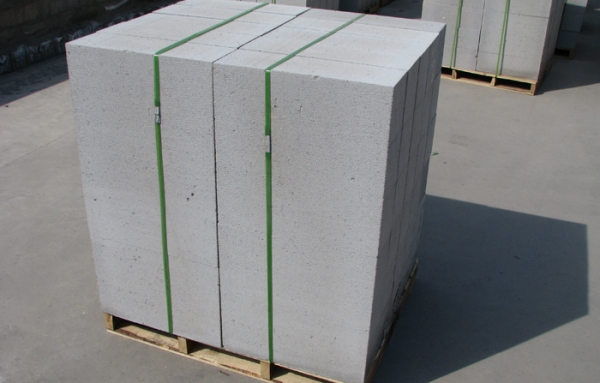

Main functions of gas dispensing block:

1 Light weight: the absolute dry unit weight is 500-600kg/m3, which is 1/4 of ordinary concrete, 1/3 of clay brick, and 1/2 of hollow brick, which is similar to wood and can float in water. It can reduce the dead weight of the building and greatly reduce the comprehensive cost of the building.

2 Fire resistance: 700 ℃, Class A incombustible refractory material. The fire resistance of 100mm thick walls can reach 225 minutes, and that of 200mm thick walls can reach 480 minutes.

3 Sound insulation: because of its porous structure, it has good sound absorption and sound insulation performance, and the wall thickness of 10 mm can reach 41 decibels.

4 Thermal insulation: due to the microporous structure inside the material, the thermal insulation effect is greatly improved. The thermal conductivity is 0.11-0.16W/MK, which is 1/4-1/5 of clay brick.

5 Impermeability: because the material is composed of many independent small pores, water absorption and moisture transmission are slow, and the time required for water absorption to saturation in the same volume is 5 times that of clay brick. When it is used in the toilet, the wall surface can be directly pasted with tiles after interface treatment.

6 Seismic resistance: the same building structure is 2 seismic levels higher than clay brick.

7 Environmental protection: the manufacturing, transportation and use processes are pollution-free, which can protect farmland, save energy and reduce consumption. It is a green building material.

8 Durability: the strength of the material is stable. When tested after one year of atmospheric exposure to the test piece, the strength is increased by 25% and remains stable after ten years.

9 Fast: It has good processability, convenient and fast construction, and shortens the construction period.