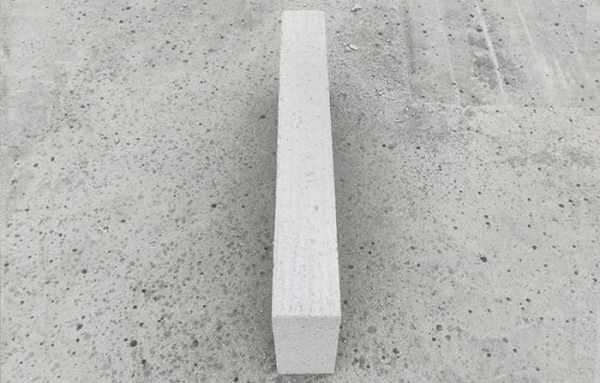

Autoclaved aerated concrete blocks It is a kind of porous concrete product made from fly ash, lime, cement, gypsum, slag, etc. as the main raw materials, adding a proper amount of air entraining agent, regulator, bubble stabilizer, through the process of batching, mixing, pouring, static stop, cutting and high-pressure steam curing.

autoclave Aerated concrete block Its construction characteristics are also very good. It can not only produce various specifications in the factory, but also sawing, planing, drilling, and nailing like wood. Because of its large size, its construction speed is also relatively fast, and it can be used as filling material for general buildings.

Autoclaved aerated concrete blocks Its unit volume weight is one third of that of clay brick, its thermal insulation performance is 3-4 times that of clay brick, its sound insulation performance is twice that of clay brick, its impermeability is more than twice that of clay brick, and its fire resistance is 6-8 times that of reinforced concrete. The masonry strength of the block is about 80% of its own strength (30% for red brick).

Autoclaved aerated concrete blocks The block is applicable to internal and external infilled walls above the ground (± 0.000) and internal infilled walls below the ground (except for walls with special requirements).

Autoclaved aerated concrete blocks It shall not be directly built on the floor or ground. C20 plain concrete wall pads with the same width as the wall thickness and no less than 0.2m in height should be poured at the root of the wall which is often subject to the alternating action of dry and wet, such as the toilet, balcony, external balcony, and the contact part between the air conditioner support plate and the masonry on the external wall; For other walls, autoclaved lime sand bricks should be used to build a wall mat with a height of not less than 0.2m at the root.

Autoclaved aerated concrete blocks Autoclave curing is a necessary condition to obtain strength and other properties, which is not only related to product performance, but also related to production efficiency and energy consumption. The optimal maintenance system not only fully and reasonably maintains the green body, so that the products can reach the design strength in a short time, but also avoids possible damage to the green body and products to the maximum extent. Because products such as tobermorite will be generated in large quantities only when the temperature is above 174.5 ℃, autoclaved aerated concrete blocks will have good comprehensive physical properties only at this temperature and pressure level for a certain time. The curing time of autoclaved aerated concrete blocks generally needs 6h~12h according to whether there is vacuum or not.

The content of this article comes from the Internet. If you have any questions, please contact us!