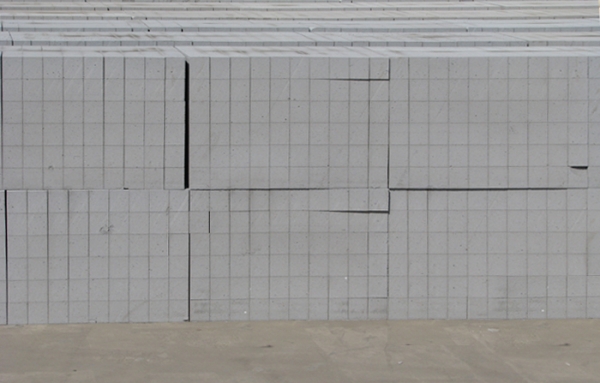

Shenyang gas filling block The manufacturer Qin Zhen Environmental Protection introduces prevention and treatment for you Autoclaved aerated concrete blocks Some specific measures for wall cracks.

1. Add structural column

One of the measures to improve the integrity of block walls is to add structural columns in the middle of the super long wall, at the corner and at the junction of the wall. autoclave Aerated concrete block The structural column in the enclosure wall or partition wall does not need to be built into a large horse tooth tenon, and the tie bar between the masonry wall and the structural column is best used! Welded steel fabric with 3.5mm mesh size of 20mm can also be made of hot-dip galvanized steel plate with thickness of 2mm. The end extending into the structural column shall be made into a dovetail shape to facilitate the concrete vibration and compaction. The steel plate laid into one end of the masonry shall be drilled with two holes and nailed into the masonry with cement steel nails (as shown in Figure 1). Reinforcement mesh or steel plate tie pieces shall be set every 500mm along the wall height or between two blocks. In addition, reinforced concrete horizontal tie beams can be added.

2. Treatment of reserved joints

In the conventional practice of masonry works, when the infilled wall is laid close to the bottom of the beam and slab, a certain gap shall be left. After the infilled wall is laid and the interval is at least 7 days, it shall be filled tightly. Generally, inclined bricks shall be used for filling. With this method, cracks may occur on the bottom surface of autoclaved aerated concrete masonry wall and reinforced concrete beam (slab). It is better to reserve a gap in the wall filled with autoclaved aerated concrete blocks, which can be controlled within 10 mm~25 mm. The gap can generally be filled with expansive cement mortar (UEA expansive agent added with 12% of the cement weight). If the gap exceeds 25 mm, it can be filled with expansive fine concrete. When embedding the exterior wall, the interior can be embedded first, and then the exterior can be embedded after the final setting of the first embedded expansion cement mortar or expansion fine aggregate concrete, so as to facilitate compaction. The expanded cement mortar or expanded fine aggregate concrete after embedding shall be kept wet for curing, or it can be embedded with flexible materials, such as glass fiber wool, mineral wool and PU foaming agent (strip), and then the surface shall be protected with elastic glass adhesive tape.

3 Tie bar or L-shaped iron piece

The crack control at the junction between the block wall and the reinforced concrete frame column or shear wall can be connected with tie bars or L-shaped iron pieces. Tie bar is better! 3.5mm mesh size 20mm welded steel fabric. When L-shaped iron parts are used, the thickness shall be up to 2mm. A gap of 10mm~15mm shall be reserved between the block wall and the reinforced concrete frame column or shear wall. After the wall masonry is completed, the gap shall be filled with flexible materials.

4 Strengthening treatment of door and window openings

When the width of the door opening is>2m, reinforced concrete frames shall be set on both sides of the opening to prevent the vibration of the door leaf from causing the vibration crack of the block wall in contact with the door frame. The window should be reinforced concrete sill beam, with both ends extending into the wall 600mm. 3 should be placed at the bottom of the next block under the window Ф 6.5mm longitudinal reinforcement, preferably! For 3.5mm mesh size 20mm welded reinforcement mesh, the length of both ends extending into the wall shall be ≥ 700mm.

5 Reduce the exposed surface of roof and wall concrete components. Because the linear expansion coefficient of reinforced concrete is larger than that of autoclaved aerated concrete blocks, under the action of thermal expansion and cold contraction cycles, the expansion and contraction of reinforced concrete components and block walls are not synchronized, which will lead to cracks in block walls or reinforced concrete beams and columns. In this case, the exposed reinforced concrete columns and beams can be designed as special-shaped structures to minimize the impact of temperature changes on concrete components.

6 Mortar joint control

To improve the thermal insulation performance of walls, not only the dry density of lightweight blocks should be reduced, but also the thermal bridges caused by large and uneven mortar joints should be avoided. The thermal conductivity of ordinary masonry mortar is about 3 times that of light block. If the thickness of mortar joint can be reduced to about 3mm, the thermal bridge generated by mortar joint can be ignored. To reduce the thickness of the mortar joint, the masonry must use a special adhesive matching the material properties of autoclaved aerated concrete, and its main technical indicators should meet the requirements of the masonry mortar in JC 890 - 2001 Masonry Mortar and Plastering Mortar for Autoclaved Aerated Concrete, as well as the requirements in Table 1.