-

Autoclaved aerated concrete block is a new type of wall material with energy saving, waste recycling and environmental protection. Autoclaved aerated concrete blocks have the advantages of light weight, heat insulation, sound insulation, heat preservation, fire prevention, earthquake resistance, easy cutting, etc. At the same time, autoclaved aerated concrete blocks also have high water absorption and slow water absorption

Published on: August 8, 2022 Clicks: 72

-

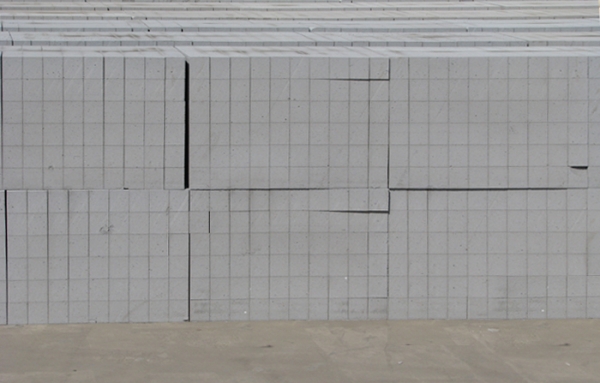

The number of cracks in autoclaved sand aerated concrete wall is more than that in shale modulus brick wall, but much less than that in fly ash brick wall. The main reasons and corresponding preventive measures are: 1. The drying shrinkage of autoclaved aerated concrete blocks is too large, and autoclaved sand aerated concrete blocks are cured by high-pressure steam, which has greatly reduced the shrinkage value of products. However, due to its composition and structure

Published on: July 29, 2022 Number of hits: 66

-

What are the differences between autoclaved aerated concrete blocks and concrete bricks? The wall materials used in the construction market before were mainly red bricks (clay bricks). At present, the state restricts the use of solid clay bricks as filling materials for frame structures in urban construction, and prohibits the use of solid bricks with strength grade below MU10 in buildings with more than 5 floors. 1、 Properties of autoclaved aerated concrete blocks

Published on: April 12, 2021 Clicks: 683

-

Interpretation of the reasons for the uneven thickness of materials in the autoclaved aerated concrete block production line, grinding materials to the required particle size for production is an important part of the aerated concrete block equipment. In this regard, ball mills play an important role. We found that in the production process, the grinding of materials is insufficient and the thickness is uneven. There are many reasons for this phenomenon. The following concrete aerated brick manufacturers will help us

Published on: 2021-05-24 Number of hits: 252

-

Autoclaved sand aerated concrete block is a porous silicate block which is made by adding aluminum powder as an air entraining agent in the ingredients of calcareous materials and siliceous materials, mixing with water, casting, forming, expanding, pre curing and cutting, and curing with high-temperature and high-pressure steam. Autoclaved sand aerated concrete blocks have four advantages that must be said. Let's take a look at them together: 1. Update of the original data:

Published on: May 28, 2020 Number of hits: 202

-

The decrease of splitting tensile strength of autoclaved aerated concrete blocks is simply caused by cracks, which will bring damage to the use of construction. Therefore, the maintenance of autoclaved aerated concrete blocks is the process that determines the composition of the product's connotation function. What problems do autoclaved aerated concrete blocks simply present when they are made? Let's introduce it. 1、 Cracks: the products out of the kettle are

Published on: December 17, 2019 Number of hits: 264

-

1. Update of the original data Autoclaved sand aerated mixed soil block stone replaced fly ash with quartz sand as the silica data, which not only improved the strength of the block, but also made a qualitative leap in impermeability, dry shrinkage, y-rays, etc. 2. Industrialized products Autoclaved sand aerated concrete masonry products produced by computer controlled automatic production line, with accurate standards

Published on: December 5, 2019 Number of hits: 663

-

The synonym of aerated concrete block aerated concrete block generally refers to aerated concrete block aerated concrete block is a new type of building material with light weight, porous, heat insulation, good fire resistance, nailing, sawing, planing and certain seismic capacity. As early as the early 1930s, China began to produce such products and widely used them. For example: Shanghai International Hotel, Shanghai Tower, Fuzhou

Published on: November 8, 2019 Number of hits: 89

-

Aerated concrete is a kind of stone that can float on the water - some people call it pumice! Autoclaved aerated concrete block manufacturer will show you more knowledge! The pores in the middle make this material very light - also known as light bricks and light walls - and also make this material block sound - also known as sound insulation brick, sound insulation brick; Because this material contains a lot of

Published on: December 6, 2020 Number of hits: 96

-

Autoclaved aerated concrete block manufacturers take you to learn more! Autoclaved aerated concrete blocks: with fly ash, lime, cement, gypsum, slag, etc. as the main raw materials, they are made by steam and other processes under the pressure of mixing, pouring, static, cutting, etc. according to the composition, participating in an appropriate amount of gas generators, regulators, bubble stabilizers. Features: As a new type of wall filling data,

Published on: September 6, 2019 Clicks: 205

-

The manufacturer of autoclaved aerated concrete blocks introduces the product classification, technical requirements, test methods, inspection rules and product quality specifications, as well as the stacking and transportation of autoclaved aerated concrete blocks. This standard is applicable to autoclaved aerated concrete blocks for civil and industrial building walls and thermal insulation materials. Autoclaved aerated concrete blocks are made of fly ash, lime, cement, gypsum, slag, etc

Published on: August 20, 2019 Number of hits: 166

-

The manufacturer of autoclaved aerated concrete block introduces that autoclaved aerated concrete block is a kind of porous concrete product made of fly ash, lime, cement, gypsum, slag, etc. as the main raw materials, with appropriate amount of air entraining agent, conditioner, bubble stabilizer, and through the process of batching, mixing, pouring, static stop, cutting and high-pressure steam curing. The construction characteristics of autoclaved aerated concrete blocks are also very excellent

Published on: February 19, 2020 Number of hits: 294

-

The manufacturer of autoclaved aerated concrete block introduces that autoclaved aerated concrete block is a solid block composed of cement, slag, sand, lime, etc. as the main raw materials to participate in the air entraining agent, which is formed by mixing and autoclaved curing. Its characteristics are: light weight, only 500~600kg/m3 for Grade 05.06; High compressive strength, up to 3.5~7.5Mpa, good thermal insulation performance

Published on: August 13, 2019 Clicks: 203

-

The manufacturer of autoclaved aerated concrete block introduces that autoclaved aerated concrete block is a kind of porous concrete product made of fly ash, lime, cement, gypsum, slag, etc. as the main raw materials, with appropriate amount of air entraining agent, conditioner, bubble stabilizer, and through the process of batching, mixing, pouring, static stop, cutting and high-pressure steam curing. 1. Light weight: dry bulk density of different grades of the product

Published on: August 8, 2019 Clicks: 177

-

Autoclaved aerated concrete block manufacturers introduce that autoclaved aerated concrete is a general term, which can be divided into sand aerated and ash aerated according to the original data "Sand" and "ash" refer to silicon oxide, one of the main raw materials. Sand refers to the use of quartz sand to provide silicon oxide, and ash refers to the use of fly ash to provide silicon oxide. Generally speaking, sand aerated concrete

Published on: August 6, 2019 Clicks: 713

-

The manufacturer of autoclaved aerated concrete block introduces that autoclaved aerated concrete block is a kind of porous concrete product made of fly ash, lime, cement, gypsum, slag, etc. as the main raw materials, with appropriate amount of air entraining agent, conditioner, bubble stabilizer, and through the process of batching, mixing, pouring, static stop, cutting and high-pressure steam curing. Aerated concrete block is the lighter type of concrete,

Published on: August 1, 2019 Number of hits: 246

-

Instructions for aerated concrete block masonry 1. The autoclaved aerated concrete block manufacturer introduced that in order to facilitate batching and reduce the on-site sawing workload during construction, the block arrangement design should be stopped during construction. 2. Before building the wall, spray proper amount of water to the block. The watering amount of water should be 8-10mm deep into the block. 3. The masonry mortar should be N5 mixed mortar

Published on: March 18, 2020 Number of hits: 107

-

1. Autoclaved aerated concrete blocks are mainly used for external infill walls and non load bearing internal partitions of buildings, and can also be combined with other materials to form a composite wall with thermal insulation function, but should not be used for the outer layer. 2. Autoclaved aerated concrete blocks should not be used in the following parts without effective measures: building elevation below ± 0.000; Long term immersion and frequent dry wet handover

Published on: July 20, 2019 Number of hits: 97

-

Autoclaved aerated concrete block manufacturers introduce that autoclaved aerated concrete is a general term, which can be divided into sand aerated and ash aerated according to the original data "Sand" and "ash" refer to silicon oxide, one of the main raw materials. Sand refers to the use of quartz sand to provide silicon oxide, and ash refers to the use of fly ash to provide silicon oxide. Generally speaking, sand aerated concrete

Published on: July 19, 2019 Number of hits: 152

-

The manufacturer of autoclaved aerated concrete block introduces that autoclaved aerated concrete block is a kind of porous concrete product made of fly ash, lime, cement, gypsum, slag, etc. as the main raw materials, with appropriate amount of air entraining agent, conditioner, bubble stabilizer, and through the process of batching, mixing, pouring, static stop, cutting and high-pressure steam curing. The unit volume weight of autoclaved aerated concrete block is

Published on: July 12, 2019 Clicks: 110

-

The manufacturer of autoclaved aerated concrete block introduces that the autoclaved aerated concrete block is economical and environmentally friendly according to the function of partition wallboard, roof panel, exterior wall panel, floor slab and other functional plates. Application range of autoclaved aerated concrete blocks: applicable to non seismic areas and areas with seismic fortification intensity of 6 to 8 degrees; It is applicable to the internal partition walls of middle grade buildings, middle grade and higher grade buildings; Applicable to all kinds of steel

Published on: July 5, 2019 Number of hits: 77

-

The manufacturer of autoclaved aerated concrete block introduces that the unit volume weight of autoclaved aerated concrete block is one third of that of clay brick, its thermal insulation performance is 3-4 times that of clay brick, its sound insulation performance is twice that of clay brick, its impermeability is more than twice that of clay brick, and its fire resistance is 6-8 times that of reinforced concrete. The construction characteristics of autoclaved aerated concrete block are also very excellent, and it cannot

Published on: July 4, 2019 Number of hits: 219

-

There are many factors affecting the strength of concrete, which can be summarized as follows: material composition, preparation methods, curing conditions and test conditions. Influence of materials on concrete strength: 1. The strength and water cement ratio of cement mainly depend on its internal cementation

Published on: June 25, 2019 Clicks: 149

-

We all hope for a better life, but a better life needs to be supported by all kinds of beautiful and useful things. Of course, we can still find a lot of useful things by looking around. It can be said that we can't live without them. We can give

Published on: June 25, 2019 Number of hits: 134

-

Ten properties of light brick: 1. Light weight: the absolute dry capacity of light brick is only 500-700Kg/m * 3, which is 1/4 of ordinary concrete, 1/3 of clay, and 1/2 of hollow block

Published on: June 25, 2019 Number of hits: 180

-

Light brick partition wall refers to a non load bearing wall for building partition formed by using light bricks or light blocks with special adhesives. Because of its light weight, high strength, water resistance and impermeability, sound insulation and fire prevention, thermal insulation, green environmental protection, and fast construction, it has been subject to the national wall reform policy for many years

Published on: June 25, 2019 Number of hits: 171

-

Qin Zhen, a manufacturer of Shenyang aerated concrete blocks, introduces some specific measures to prevent cracks in the wall of autoclaved aerated concrete blocks.

Published on: June 25, 2019 Clicks: 221

-

The current housing situation in China cannot guarantee that the per capita area is abundant. Therefore, some families need to make some partitions in their homes to create multi-functional space as much as possible. Generally speaking, partition materials are as follows: light brick, glass brick, glass, wood, gypsum board, etc

Published on: June 25, 2019 Number of hits: 146

-

Steam aerated concrete block, like other concrete, is composed of several materials. Therefore, there is a problem of which materials to use and how many to use each material. The percentage of various materials used in the ingredients is called mix proportion. For aerated concrete, to determine a good mix ratio, the following requirements must be met: (1) The products have good

Published on: June 25, 2019 Clicks: 154

-

Aerated concrete in China is the earliest and most productive type of new wall materials. After nearly 50 years of development, it has formed a complete industrial system of material production, equipment manufacturing, supporting material supply, design and scientific research. According to incomplete statistics, the output of aerated concrete in China is close to 70 million cubic meters, ranking first in the world. In the process of wall material innovation,

Published on: June 25, 2019 Number of hits: 120

-

1、 Material requirements

Published on: June 25, 2019 Clicks: 135