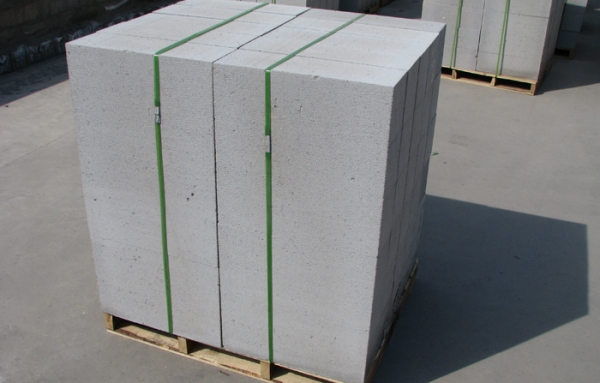

Autoclaved aerated concrete blocks Manufacturer's introduction Autoclave Aerated concrete block It is a kind of porous concrete product made of fly ash, lime, cement, gypsum, slag, etc. as the main raw materials, with appropriate amount of air entraining agent, conditioner, bubble stabilizer, through the process of batching, mixing, pouring, static stop, cutting and high-pressure steam curing.

The construction characteristics of autoclaved aerated concrete block are also very excellent. It can not only produce various specifications in the factory, but also stop sawing, planing, drilling, and nailing like wood. Because of its relatively large volume, the construction speed is relatively fast, which can be used as filling materials for ordinary buildings.

Autoclaved aerated concrete block is a kind of porous concrete product made of fly ash, lime, cement, gypsum, slag, etc. as the main raw materials, with appropriate amount of air entraining agent, conditioning agent, bubble stabilizer, through the process of batching, mixing, pouring, static stop, cutting and high-pressure steam curing.

Main technical indicators to be considered when selecting autoclaved aerated concrete blocks: strength, dry density, dry shrinkage value, frost resistance and thermal conductivity, radioactivity.

The aerated concrete block has thermal insulation, which is more energy-saving. It is also a great advantage to speed up the low thermal conductivity of concrete block equipment. For the appearance of relevant materials, if the building uses aerated concrete blocks, the temperature of the building is more than one degree higher than that of those buildings that do not use aerated concrete blocks. Aerated concrete blocks are good in appearance pressure resistance. Aerated concrete block can effectively relieve the pressure of land.

The content of this article comes from the Internet. If you have any questions, please contact us!