1. Update of original data

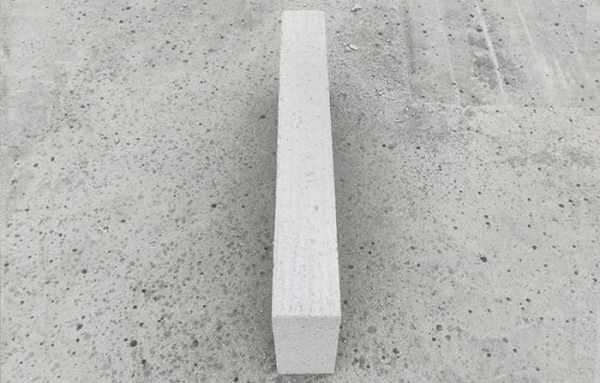

The autoclaved sand aerated mixed soil block stone uses quartz sand instead of fly ash as silica material, which not only improves the strength of the block, but also makes a qualitative leap in impermeability, dry shrinkage, y-rays, etc.

2. Industrialized products

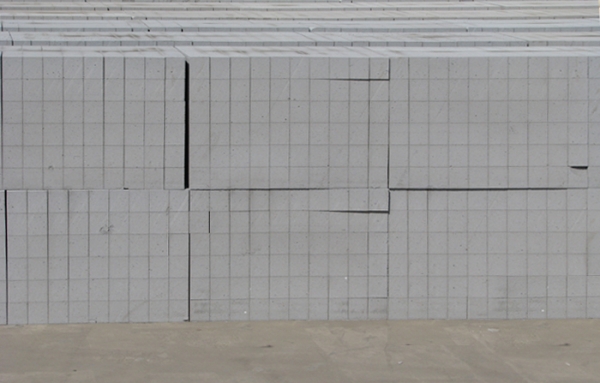

Autoclaved sand Aerated concrete block The products produced by the automatic production line controlled by the stone computer have accurate standards and small errors, and their quality is always better than the national standard of high-quality products. The industrialized devices can achieve dry operation and high efficiency.

3. Supporting wall post treatment

Due to the accurate size of autoclaved sand aerated concrete block products, mortar masonry is not necessary, but adhesive masonry is used instead. The mortar joint is only 2-3mm, and the wall surface can be painted with putty instead of painting, fundamentally solving the persistent problem of aerated concrete block painting cracks.

4. Flexible and diverse use parts

Autoclaved aerated concrete blocks The finished product can be used as both board and block, and the board can also be finished with veneer. The exterior decoration can be completed only by spraying paint. There are many parts to use and the function is complete.

The content of this article comes from the network. If you have any questions, please contact us!