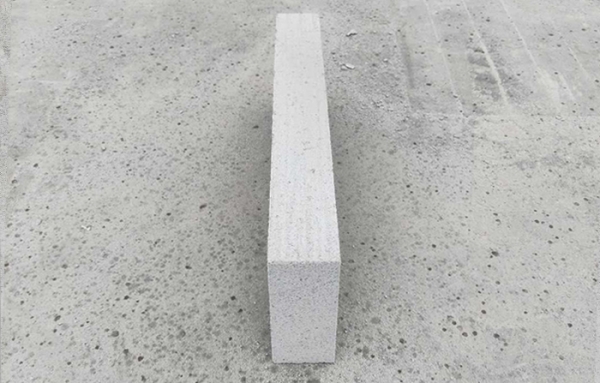

Shenyang gas filling block The equipment is a complete set of equipment. The device contains more. In the process of application, please pay attention to the protection of each equipment to ensure product quality. If the equipment is of excellent quality, please make sure to protect it.

First, yes Aerator block The raw material processing part of the equipment shall be protected to ensure the accuracy of the measurement control system. Specific completion method: the traditional symmetrical quantity system uses component verification to check whether each unloading valve is sealed well. If the unloading height and the bulk density fluctuate abnormally, check from the beginning immediately to ensure that the proportion of aerated concrete is correct. Together, keep the control room and each weighing control system clean. The protection and maintenance shall be carried out as planned to ensure the accuracy of the measurement control system.

2、 Maintenance of mixer in the process of pulping: clean the mixer regularly, and replace the worn mixing blades in time after the maintenance of the mixer is completed to ensure the integrity of the mixing paddle and accessories, and ensure the integrity of the mixing paddle and accessories. Use a mixed system. Normal to ensure the whole body's writing.

Third, check and repair the nursing room regularly before the fixed stay, so that all targets can meet the pre feeding requirements of the aerated concrete body, and ensure the subsequent blank cutting and steaming process.

4、 Protection of cutting machine: transport the blank out of the pre protection room, and the cutting machine can cut the size as required. The shape and size of the lathe are flexible and diverse, and large-scale mechanized production has been completed. The working condition of the cutting machine directly affects the precision of the cutting scale and the cutting effect. Therefore, the protection of cutting equipment, transmission equipment, wire positioning equipment and other equipment should be strengthened to find and correct the defects of the equipment.

Fifth, the stability of the billet running process and the protection of the track: the strength of the aerated concrete body without high-pressure sterilization is very low. Therefore, it is necessary to ensure the stability of the transportation process in order to reduce the damage of the billet structure in the transportation process. Then reduce the impact on product quality. Therefore, it is necessary to ensure that the track during transportation is stable and free of sundries, and that the lifting equipment and steering equipment can operate smoothly, such as the protection and maintenance of slings, driving wheels, guide wheels and other equipment.

In short, the accuracy of measurement, the uniformity of mixing, the accuracy of incision scale, the smoothness of carcass operation and the continuity of production process are undoubtedly the factors that affect inflation.

The content of this article comes from the network. If you have any questions, please contact me to delete it!