Journalism

-

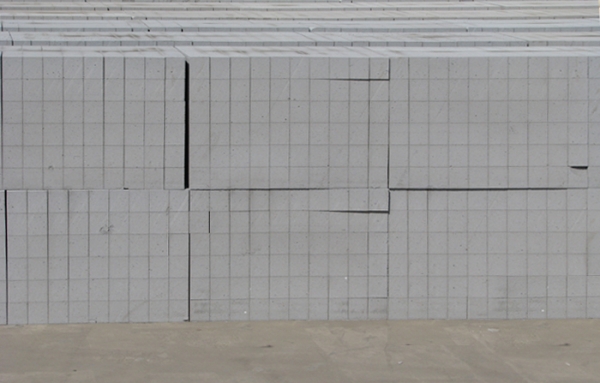

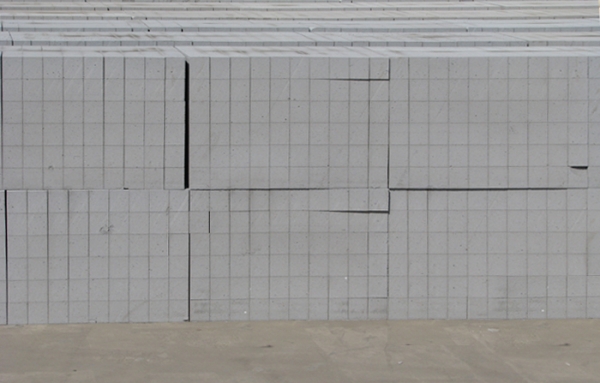

Aerated concrete in China is the earliest developed and most productive type of new wall materials. After nearly 50 years of development, it has formed a complete industrial system of material production, equipment manufacturing, supporting material supply, design and scientific research. According to incomplete statistics, the output of aerated concrete in China is close to 70 million cubic meters, ranking first in the world. In the process of wall material innovation,

Published on: June 25, 2019 Clicks: 118

-

During the construction of autoclaved aerated concrete blocks, certain precautions should also be taken. Before and during masonry, attention should be paid to the following: 1. Requirements before masonry: 1. There should be rain proof measures during the transportation of blocks. It is strictly prohibited to drop, throw or dump the blocks during transportation and loading. 2. After the blocks enter the site, rain proof measures shall be taken. Blocks shall not be stacked in the open during construction

Published on: June 27, 2019 Number of hits: 163

-

Since the reform and opening up, the domestic economy and people's life philosophy have undergone tremendous changes. The income level of the Chinese people has greatly improved, and their living conditions are also constantly improving. Now people live in western-style houses, in various elegant neighborhoods, and gradually begin to have environmentally friendly, economical, and fast living

Published on: June 27, 2019 Clicks: 183

-

What are the differences between autoclaved aerated concrete blocks and concrete bricks? The wall materials used in the construction market before were mainly red bricks (clay bricks). At present, the state restricts the use of solid clay bricks as filling materials for frame structures in urban construction, and prohibits the use of solid bricks with strength grade below MU10 in buildings with more than 5 floors. 1、 Properties of autoclaved aerated concrete blocks

Published on: April 12, 2021 Clicks: 616

-

Autoclaved aerated concrete block is a new type of wall material with energy saving, waste recycling and environmental protection. Autoclaved aerated concrete blocks have the advantages of light weight, heat insulation, sound insulation, heat preservation, fire prevention, earthquake resistance, easy cutting, etc. At the same time, autoclaved aerated concrete blocks also have high water absorption and slow water absorption

Published on: August 8, 2022 Clicks: 65

-

Qin Zhen, a manufacturer of Shenyang aerated concrete blocks, introduces some specific measures to prevent cracks in the wall of autoclaved aerated concrete blocks.

Published on: June 25, 2019 Number of hits: 217

-

The manufacturer of autoclaved aerated concrete block introduces that the unit volume weight of autoclaved aerated concrete block is one third of that of clay brick, its thermal insulation performance is 3-4 times that of clay brick, its sound insulation performance is twice that of clay brick, its impermeability is more than twice that of clay brick, and its fire resistance is 6-8 times that of reinforced concrete. The construction characteristics of autoclaved aerated concrete block are also very excellent, and it cannot

Published on: July 4, 2019 Number of hits: 218

-

The manufacturer of autoclaved aerated concrete block introduces that the autoclaved aerated concrete block is economical and environmentally friendly according to the function of partition wallboard, roof panel, exterior wall panel, floor slab and other functional plates. Application range of autoclaved aerated concrete blocks: applicable to non seismic areas and areas with seismic fortification intensity of 6 to 8 degrees; It is applicable to the internal partition walls of middle grade buildings, middle grade and higher grade buildings; Applicable to all kinds of steel

Published on: July 5, 2019 Number of hits: 73

-

The manufacturer of autoclaved aerated concrete block introduces that autoclaved aerated concrete block is a kind of porous concrete product made of fly ash, lime, cement, gypsum, slag, etc. as the main raw materials, with appropriate amount of air entraining agent, conditioner, bubble stabilizer, and through the process of batching, mixing, pouring, static stop, cutting and high-pressure steam curing. The unit volume weight of autoclaved aerated concrete block is

Published on: July 12, 2019 Number of hits: 108

-

Autoclaved aerated concrete block manufacturers introduce that autoclaved aerated concrete is a general term, which can be divided into sand aerated and ash aerated according to the original data "Sand" and "ash" refer to silicon oxide, one of the main raw materials. Sand refers to the use of quartz sand to provide silicon oxide, and ash refers to the use of fly ash to provide silicon oxide. Generally speaking, sand aerated concrete

Published on: July 19, 2019 Number of hits: 146

-

1. Autoclaved aerated concrete blocks are mainly used for external infill walls and non load bearing internal partitions of buildings, and can also be combined with other materials to form a composite wall with thermal insulation function, but should not be used for the outer layer. 2. Autoclaved aerated concrete blocks should not be used in the following parts without effective measures: building elevation below ± 0.000; Long term immersion and frequent dry wet handover

Published on: July 20, 2019 Number of hits: 95

-

The manufacturer of autoclaved aerated concrete block introduces that autoclaved aerated concrete block is a kind of porous concrete product made of fly ash, lime, cement, gypsum, slag, etc. as the main raw materials, with appropriate amount of air entraining agent, conditioner, bubble stabilizer, and through the process of batching, mixing, pouring, static stop, cutting and high-pressure steam curing. Aerated concrete block is the lighter type of concrete,

Published on: August 1, 2019 Number of hits: 210

-

Autoclaved aerated concrete block manufacturers introduce that autoclaved aerated concrete is a general term, which can be divided into sand aerated and ash aerated according to the original data "Sand" and "ash" refer to silicon oxide, one of the main raw materials. Sand refers to the use of quartz sand to provide silicon oxide, and ash refers to the use of fly ash to provide silicon oxide. Generally speaking, sand aerated concrete

Published on: August 6, 2019 Number of hits: 687

-

The manufacturer of autoclaved aerated concrete block introduces that autoclaved aerated concrete block is a kind of porous concrete product made of fly ash, lime, cement, gypsum, slag, etc. as the main raw materials, with appropriate amount of air entraining agent, conditioner, bubble stabilizer, and through the process of batching, mixing, pouring, static stop, cutting and high-pressure steam curing. 1. Light weight: dry bulk density of different grades of the product

Published on: August 8, 2019 Number of hits: 134

-

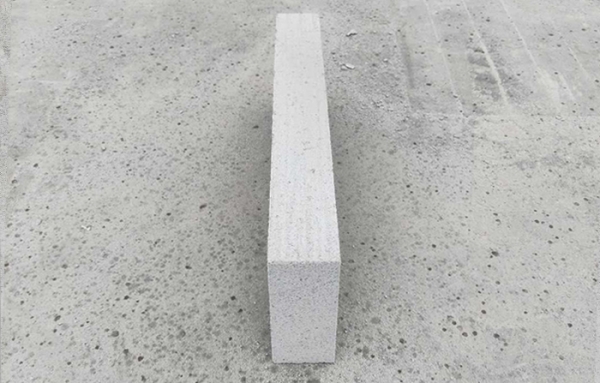

The manufacturer of autoclaved aerated concrete block introduces that autoclaved aerated concrete block is a solid block composed of cement, slag, sand, lime, etc. as the main raw materials to participate in the air entraining agent, which is formed by mixing and autoclaved curing. Its characteristics are: light weight, only 500~600kg/m3 for Grade 05.06; High compressive strength, up to 3.5~7.5Mpa, good thermal insulation performance

Published on: August 13, 2019 Clicks: 199

-

The manufacturer of autoclaved aerated concrete block introduces that autoclaved aerated concrete block is a kind of porous concrete product made of fly ash, lime, cement, gypsum, slag, etc. as the main raw materials, with appropriate amount of air entraining agent, conditioner, bubble stabilizer, and through the process of batching, mixing, pouring, static stop, cutting and high-pressure steam curing. The construction characteristics of autoclaved aerated concrete blocks are also very excellent

Published on: February 19, 2020 Number of hits: 290

-

The manufacturer of autoclaved aerated concrete blocks introduces the product classification, technical requirements, test methods, inspection rules and product quality specifications, as well as the stacking and transportation of autoclaved aerated concrete blocks. This standard is applicable to autoclaved aerated concrete blocks for civil and industrial building walls and thermal insulation materials. Autoclaved aerated concrete blocks are made of fly ash, lime, cement, gypsum, slag, etc

Published on: August 20, 2019 Clicks: 164

-

Autoclaved aerated concrete block manufacturers take you to learn more! Autoclaved aerated concrete blocks: with fly ash, lime, cement, gypsum, slag, etc. as the main raw materials, they are made by steam and other processes under the pressure of mixing, pouring, static, cutting, etc. according to the composition, participating in an appropriate amount of gas generators, regulators, bubble stabilizers. Features: As a new type of wall filling data,

Published on: September 6, 2019 Clicks: 203

-

Autoclaved aerated concrete block is a kind of porous concrete product made from fly ash, lime, cement, gypsum, slag, etc. as the main raw materials, adding appropriate amount of air entraining agent, regulator, bubble stabilizer, through the process of batching, mixing, pouring, static stop, cutting and high-pressure steam curing. The construction characteristics of autoclaved aerated concrete blocks are also very good, which can not only be produced in the factory

Published on: October 10, 2019 Clicks: 262

-

Autoclaved aerated concrete block masonry is generally used for infilled walls, and the strength grade of the blocks used is generally A3.5 for partition walls and A5 for exterior walls. Mortar strength shall not be less than M5. Before building autoclaved aerated concrete blocks, block arrangement diagram shall be drawn according to the plan and elevation of the building. The number of bricks and the height of the bricks are drawn on the number of bricks and the height of the bricks

Published on: October 12, 2019 Clicks: 164

-

Main technical indicators to be considered when selecting autoclaved aerated concrete blocks: strength, dry density, dry shrinkage value, frost resistance, thermal conductivity, radioactivity. 1. It is mainly used for the external infill wall and non load bearing internal partition wall of the building, and can also be combined with other materials to form a composite wall with thermal insulation function, but it is not suitable for the outermost layer. 2. Autoclaved aerated concrete block, if not effective

Published on: October 15, 2019 Clicks: 110

-

The construction characteristics of autoclaved aerated concrete block are also very good. It can not only produce various specifications in the factory, but also can be sawed, planed, drilled and nailed like wood. Because of its large volume, the construction speed is relatively fast, and it can be used as the filling material for general buildings. Key points for selection: 1. It is mainly used for external infill wall and non load bearing internal partition wall of buildings, or

Published on: October 29, 2019 Clicks: 132

-

1. Update of the original data Autoclaved sand aerated mixed soil block stone replaced fly ash with quartz sand as the silica data, which not only improved the strength of the block, but also made a qualitative leap in impermeability, dry shrinkage, y-rays, etc. 2. Industrialized products Autoclaved sand aerated concrete masonry products produced by computer controlled automatic production line, with accurate standards

Published on: December 5, 2019 Number of hits: 650

-

The decrease of splitting tensile strength of autoclaved aerated concrete blocks is simply caused by cracks, which will bring damage to the use of construction. Therefore, the maintenance of autoclaved aerated concrete blocks is the process that determines the composition of the product's connotation function. What problems do autoclaved aerated concrete blocks simply present when they are made? Let's introduce it. 1、 Cracks: the products out of the kettle are

Published on: December 17, 2019 Number of hits: 259

-

Autoclaved aerated concrete block equipment has good processing function. Capable of sawing, planing, nailing, grinding, and thread processing in the production process. It brings great convenience and sensitivity to construction. When the temperature of aerated concrete block equipment is lower than 600 ° C, the compressive strength will be slightly increased. When the temperature is about 600 ° C, the compressive strength is close to normal temperature

Published on: February 19, 2021 Clicks: 93

-

Features and process principle of autoclaved aerated concrete block 1. Features of autoclaved aerated concrete block 1. The connection between the block and the main frame is fixed with cement nails, without pre embedding iron parts on the concrete frame structure, the construction is fast and simple, and the construction period is shortened. 2. The top gap of the wall shall be filled with polystyrene foaming agent to fix the wall, sound insulation and heat preservation. 3. Special waterproof plastering on wall surface

Published on: February 14, 2020 Clicks: 316

-

The manufacturer of autoclaved aerated concrete blocks introduces the product classification, skill requirements, test methods, inspection rules and product quality specifications, as well as the stacking and transportation of autoclaved aerated concrete blocks. This specification is applicable to autoclaved aerated concrete blocks for civil and industrial building walls and thermal insulation materials. Autoclaved aerated concrete blocks are made of fly ash, lime, cement, gypsum, slag, etc

Published on: January 31, 2021 Clicks: 114

-

In the current wall building process, autoclaved aerated concrete blocks are mainly used for new wall materials, and this skill has been widely used. This kind of data is mainly used in the construction of frame structure, which has replaced the data of clay solid brick masonry. This kind of data takes cement, lime, gypsum, river sand as the original data, and is made into microporous blocks by foaming aluminum powder, forming, autoclaving and other processes

Published on: March 23, 2020 Number of hits: 121

-

Scope of application Autoclaved aerated concrete blocks are applicable to all kinds of exterior and interior infilled walls above the ground (± 0.000) and interior infilled walls below the ground (except for walls with special requirements).

Published on: April 14, 2020 Clicks: 155

-

Notice on application of autoclaved aerated concrete blocks? The manufacturer of autoclaved aerated concrete block introduces that the autoclaved aerated concrete block is economical and environmentally friendly according to the function of partition wallboard, roof panel, exterior wall panel, floor slab and other functional plates. Application range of autoclaved aerated concrete blocks: applicable to non seismic areas and areas with seismic fortification intensity of 6 to 8 degrees; Applicable to middle grade construction

Published on: May 6, 2020 Clicks: 114

-

Autoclaved aerated concrete blocks shall not be directly laid on the floor or ground. With regard to the root of the wall that is often subject to the effect of dry and wet replacement, such as the toilet, terrace, external balcony, and the contact part between the air conditioner support plate and the masonry on the external wall, C20 plain concrete wall pads with the same width as the wall thickness and a height of no less than 0.2m should be poured; For other walls, autoclaved lime sand bricks should be used at the root

Published on: May 12, 2020 Number of hits: 278

-

Autoclaved aerated concrete block, also known as light brick, aerated block, is a kind of lightweight, microporous new wall material processed with fly ash, lime, cement, gypsum, etc. as the primary raw material, and added with appropriate amount of generating agent. It has the characteristics of light volume weight, good thermal insulation, sound insulation, fire prevention, and processability, and is widely used in the household wall Partition wall and concrete

Published on: May 18, 2020 Number of hits: 269

-

The number of cracks in autoclaved sand aerated concrete wall is more than that in shale modulus brick wall, but much less than that in fly ash brick wall. The main reasons and corresponding preventive measures are: 1. The drying shrinkage of autoclaved aerated concrete blocks is too large, and autoclaved sand aerated concrete blocks are cured by high-pressure steam, which has greatly reduced the shrinkage value of products. However, due to its composition and structure

Published on: July 29, 2022 Clicks: 62

-

In the current wall building process, the new wall material mainly uses autoclaved aerated concrete blocks, which has been widely used. This kind of material is mainly used in frame type structural buildings and has replaced the clay solid brick masonry material. This material uses cement, lime, gypsum and river sand as raw materials, and uses aluminum powder foaming, molding, autoclaving and other processes to make micro

Published on: June 25, 2019 Clicks: 367

-

Sand aerated block is a kind of environment-friendly building material now. We may not see many of them in ordinary times, but does it sound inconceivable to those who need additives in the manufacturing process of aerated block? Not only food, but also building materials. Don't worry

Published on: June 25, 2019 Number of hits: 102

-

Interpretation of the reasons for the uneven thickness of materials in the autoclaved aerated concrete block production line, grinding materials to the required particle size for production is an important part of the aerated concrete block equipment. In this regard, ball mills play an important role. We found that in the production process, the grinding of materials is insufficient and the thickness is uneven. There are many reasons for this phenomenon. The following concrete aerated brick manufacturers will help us

Published on: 2021-05-24 Number of hits: 250